CIRCULAR

WASTE REDUCTION

CIRCULAR

WASTE REDUCTION

Innovative systems which turn organic waste products into compost on location

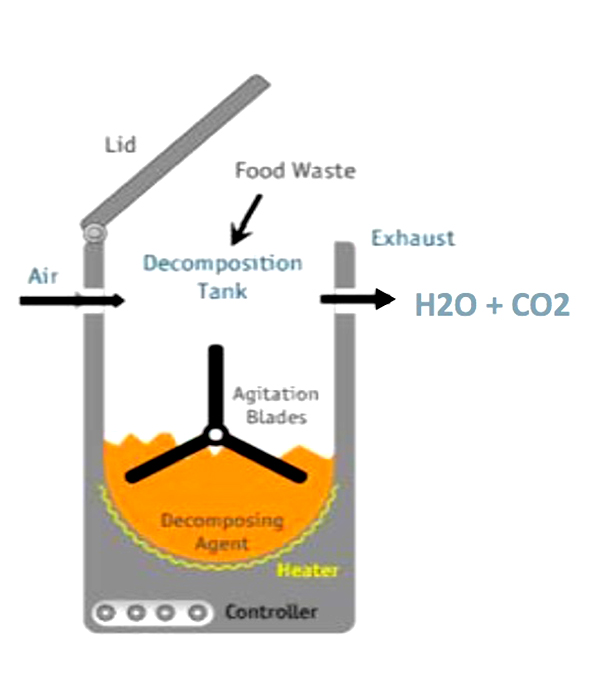

The contents of the tank are heated so that moisture is extracted from the mix at an accelerated rate. Within 24 hours the bacteria turns all biodegradable waste (including fruit peel, processed food and coffee grounds) into dry compost which has only 15 percent of the original waste volume.

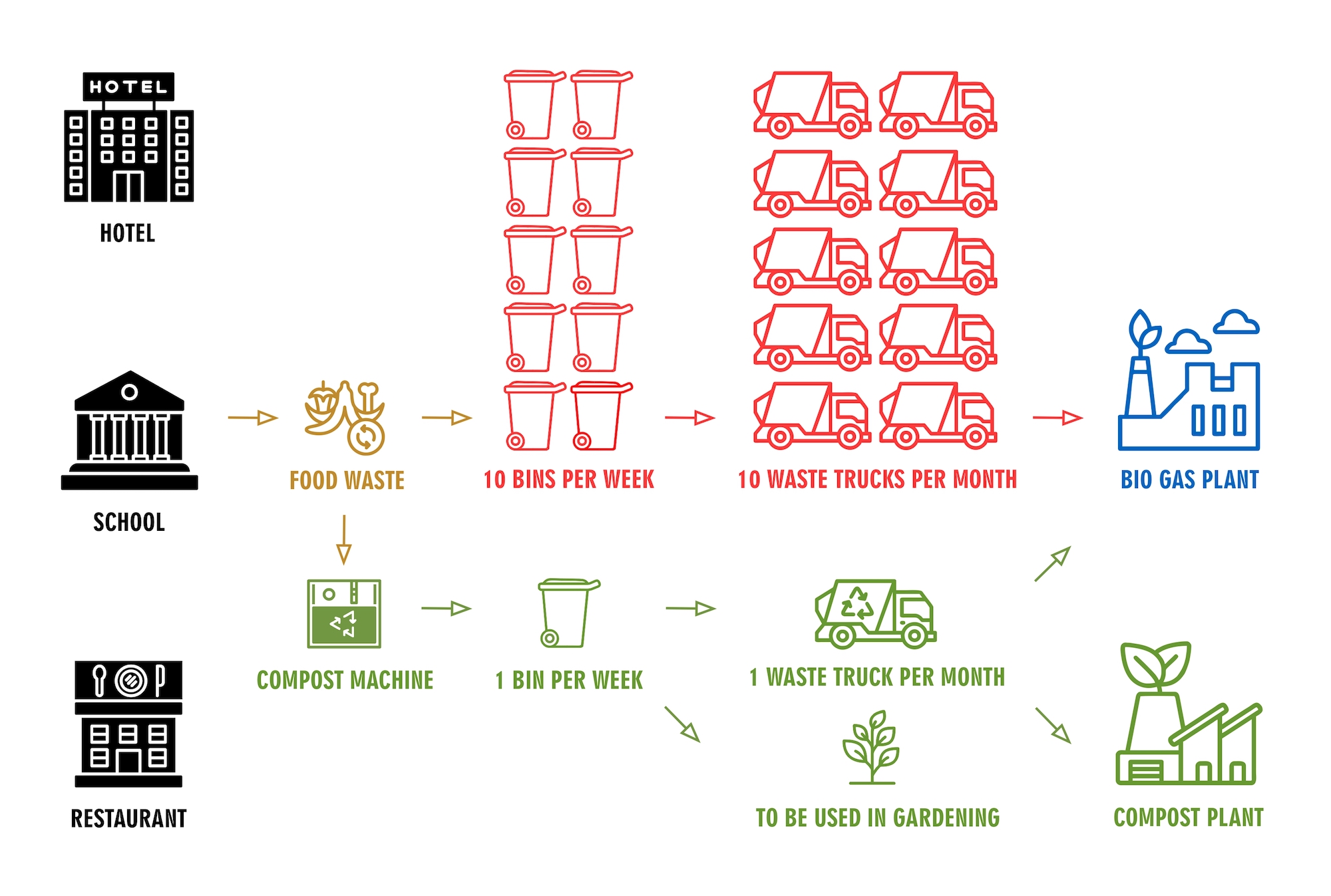

When composting 40 kilos of organics waste per day, the Composter becomes cost-effective within 2-5 years of purchase. All you need is a power supply and connection to an air outlet.

- Organic waste becomes a valuable product; compost

- Less waste, therefore lower costs

- Reduce transport means less pollution

- Reduced need for fertilizer prevents exhaustion of fossil sources and results in less pollution

- Your compost becomes a unique symbol of your organisation’s sustainable management

- Proud employees; involved family members, suppliers and enthusiastic clients

85% sustainable savings on organic waste flows

Composting systems

- tailored to the requirements of our customers

Bacteria cultures

- tailored to specific waste streams

Systems programming

- tailored to a swift and efficient composting process

Continuous research for new cultures

- food waste

- compostable packaging

- bio-plastics

A Unique composting concept

Environmentally friendly, simple and efficient:

- Waste can be added at any given time. Emptying is only one time per week.

- During the composting process, the tank is heated and waste is mixed and broken down by the rotating blades.

- After 24 hours of composting and mixing, waste has been broken down by the bacteria. What remains is water vapour and carbon dioxide.

- The special ventilation ensures air intake which will allow fermentation to take place in an open space. The released gas is drained away.

Would you like to reduce your waste and save money?

A solution for every situation

From 30 kilograms to 270 kilograms a day

EC – 20

Daily capacity:

55 kg per day

EC – 30

Daily capacity:

82 kg per day

EC – 50

Daily capacity:

137 kg per day

EC – 100

Daily capacity:

270 kg per day

EC – 1000 range

Daily capacity:

≥ 1.000 kg per day

A solution for every situation

From 30 kilograms to 270 kilograms a day

EC – 30

Daily capacity:

82 kg per day

EC – 50

Daily capacity:

137 kg per day

EC – 100

Daily capacity:

270 kg per day

EC – 1000 range

Daily capacity:

≥ 1.000 kg per day

More solutions

We offer complete customised solutions based on our farmers needs.

Scale your business as you grow.

LED lights for edible plants

Finnish manufacturer Valoya

Tailored LED lighting spectrums are custom-made to the crop type to ensure the energy invested in growth light technology will be converted efficiently into light that crops require.

Our experienced team is your best resource!

Contact us to get personalised advice and assistance as you work on your business plan, site, and budget.

All rights reserved ® 2023

Our experienced team is your best resource!

Contact us to get personalised advice and assistance as you work on your business plan, site, and budget.

All rights reserved ® 2023